Different Types of Reel Jack Stands Explained

Author:jiujiu Release time:2025-11-18 15:35:30 Number of views:90order

Heavy-duty Reel Jack Stands are indispensable tools for handling cable reels in industrial, utility, and construction environments. These stands provide a stable lifting platform, ensuring that reels remain securely elevated during pulling, unwinding, or rewinding operations. Technicians, project planners, and even manufacturer-level production evaluators benefit from understanding the distinctions between the major types of jack stands used in the field.

This guide breaks down the different categories of reel jack stands, highlighting their structural features, operating principles, and ideal use cases.

Why Reel Jack Stands Are Critical in Cable Handling

Cable reels—especially those carrying high-voltage power cables, fiber-optic bundles, or heavy-duty industrial wiring—often weigh hundreds of kilograms. Managing them without proper support equipment is impractical and unsafe. Reel jack stands provide:

·Controlled lifting

·Stable alignment for smooth payout

·Protection for cable and reel surfaces

·Safer working conditions

·Consistent tension management

Because reel handling conditions vary widely across job sites, the right type of stand makes a significant difference in overall workflow efficiency.

Major Types of Reel Jack Stands

Below is a detailed overview of the most commonly used reel jack stand designs and how each one serves different operational needs.

1. Mechanical Screw-Type Reel Jack Stands

This traditional design uses a threaded lifting column that raises or lowers the spindle through manual rotation. It is valued for robustness and long-term reliability.

Key advantages:

·Precise height adjustment

·Excellent load stability

·No power or hydraulics needed

·Works well in rugged environments

These stands are well suited for general-purpose installations, field line work, and situations where simplicity is preferred.

2. Hydraulic-Assisted Reel Jack Stands

Hydraulic models incorporate a pump mechanism—either hand-operated or foot-actuated—that allows heavy reels to be lifted with minimal physical effort.

Why they’re useful:

·Smooth lifting of extremely heavy reels

·Reduced technician exertion

·Fine control over reel elevation

·Ideal for frequent daily use

Hydraulic stands are commonly chosen for industrial facilities, utility crews handling bulk cable reels, and large outdoor deployment projects.

3. Auto-Locking Telescopic Reel Stands

These stands use a telescoping column system that locks automatically at set intervals. Their design emphasizes convenience and quick adjustments.

Notable features:

·Rapid height selection

·Light-to-medium weight construction

·Secure locking points

·Faster setup than screw-type systems

They perform best in fast-paced environments where cable reels need to be swapped or repositioned frequently.

4. Roller-Saddle Reel Jack Stands

In these designs, the spindle rests on roller bearings or low-friction saddles mounted at the top of each stand. This significantly improves reel rotation.

Performance benefits:

·Smooth, controlled payout during pulls

·Reduced friction on the spindle

·Lower cable tension fluctuations

·Enhanced safety on long-distance pulls

Roller-top stands are commonly used in underground cable placement, fiber-optic backbone deployment, and large conduit installations.

5. Heavy-Duty A-Frame Reel Stands

The triangular A-frame profile distributes load efficiently and offers excellent rigidity. These stands often feature adjustable posts for spindle positioning.

Strengths:

·Strong geometric structure

·High load-bearing capacity

·Broad footprint for stability

·Reliable on uneven ground

These stands are ideal for outdoor industrial zones, construction sites, and locations where strong lateral stability is required.

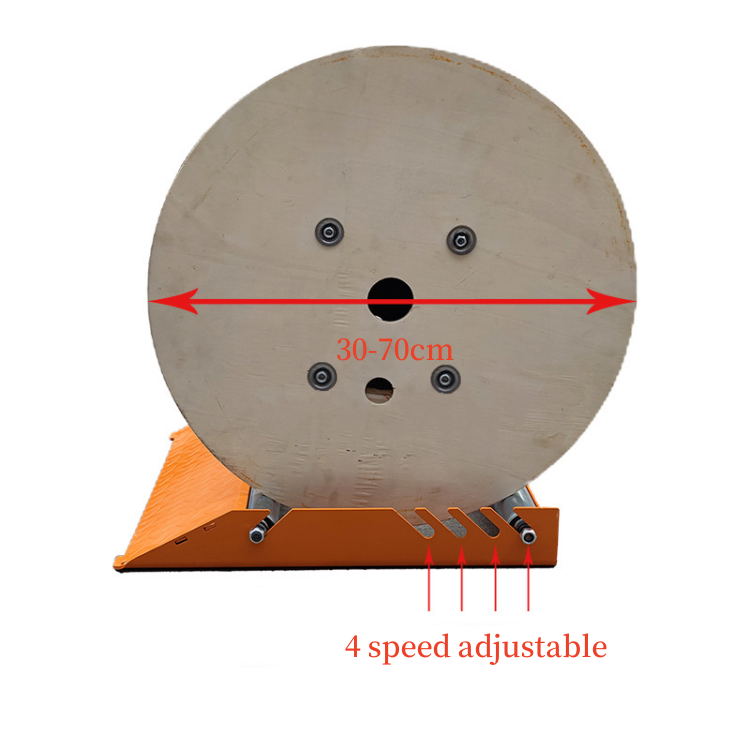

6. Compact and Portable Reel Stands

Designed for small or mid-sized reels, portable stands are lightweight, foldable, and easy to move from job to job.

Key characteristics:

·Aluminum or thin-wall steel fabrication

·Collapsible frames

·Quick-release locking systems

These stands are commonly used for telecom service drops, low-voltage wiring, and maintenance tasks requiring frequent mobility.

7. Ultra-Heavy Industrial Reel Jack Stands

These are purpose-built for extreme loads and continuous duty cycles. Structural reinforcements, oversized spindles, and wide bases are typically included.

Advantages:

·Handles the largest reels used in industry

·Withstands high pulling tension

·Long operational lifespan

·Designed for demanding daily environments

Such stands are often utilized at manufacturing facilities, warehouse cable drum storage areas, and large electrical infrastructure projects. They are especially relevant when a manufacturer provides batch supply for sizeable reel inventories.

Selecting the Right Type of Reel Jack Stand

To choose the correct stand type, consider the following:

1. Reel Mass and Dimensions

Matching the stand to the reel’s diameter, width, and total weight ensures balanced lifting and safe operation.

2. Field Conditions

Soft ground, uneven surfaces, or limited workspace may require reinforced bases or A-frame configurations.

3. Operation Frequency

For repeated daily use, hydraulic or industrial-strength designs are optimal.

4. Precision Requirements

Manual screw systems deliver fine adjustment, while telescopic and hydraulic models provide faster, smoother control.

5. Portability

Compact stands work well for technicians who must travel between job sites.

Safety Considerations for All Types

Regardless of the stand type selected, safe operation remains essential:

·Always level both stands before lifting

·Confirm that the spindle is fully seated and locked

·Avoid exceeding the stand’s rated capacity

·Inspect all welds, hardware, and bearing surfaces

·Ensure legs or bases have solid ground contact

·Maintain equal height adjustment between stands

Well-maintained reel jack stands significantly reduce the risk of reel instability, drops, or uncontrolled rotation.

Conclusion

Heavy-duty Reel Jack Stands come in several configurations, each with specialized strengths tailored to different reel-handling demands. From mechanical screw models to hydraulic and roller-saddle designs, selecting the right type ensures safer lifting, smoother cable payout, and greater operational efficiency. Understanding how each type functions helps installers, supervisors, and production teams maintain consistent quality and reliable performance across a variety of work environments.

References

GB/T 7714:Hao C. Structural Mechanics Analysis of Multi-row Cable Drum of Port Machinery Based on ANSYS Workbench[J]. Academic Journal of Science and Technology, 3(3): 2022.

MLA:Hao, Chen. "Structural Mechanics Analysis of Multi-row Cable Drum of Port Machinery Based on ANSYS Workbench." Academic Journal of Science and Technology 3.3: 2022.

APA:Hao, C. Structural Mechanics Analysis of Multi-row Cable Drum of Port Machinery Based on ANSYS Workbench. Academic Journal of Science and Technology, 3(3), 2022.