Safety Tips for Using Cable Jack Stands on Site

Author:jiujiu Release time:2025-12-12 18:56:31 Number of views:152order

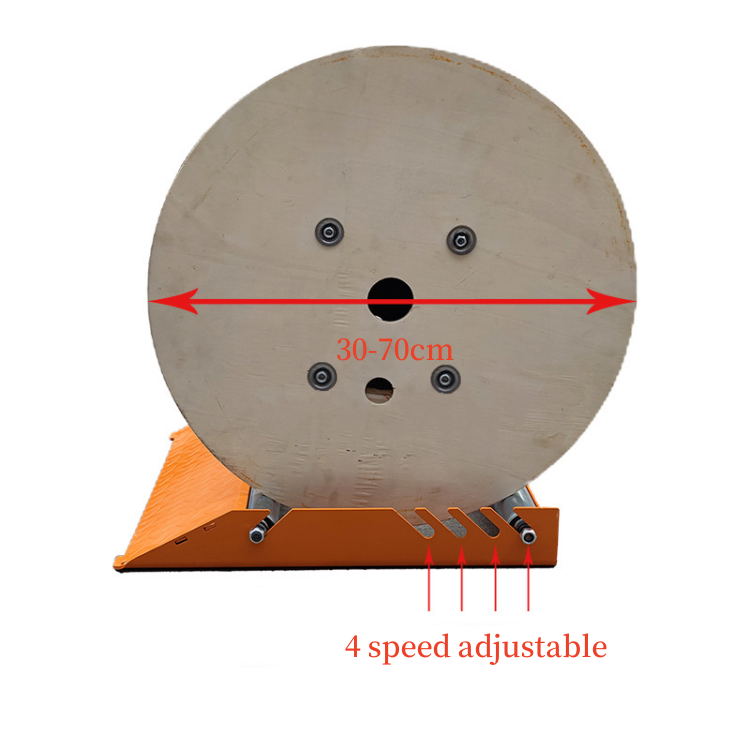

On construction sites, utility projects, and industrial installations, Cable Jack Stands are critical for lifting and supporting cable reels during deployment. Their primary function is to stabilize heavy drums and allow smooth cable payout, but safety depends on correct usage and equipment integrity. When the stands are not positioned properly or when reels exceed capacity, risks such as tipping, uneven lifting, and uncontrolled rotation can arise. This is one reason why many contractors choose stands produced by a dedicated Manufacturer with strong Production standards and dependable bulk supply.

To ensure efficient and hazard-free operations, the following safety tips should be followed whenever Cable Jack Stands are used on site.

1. Know the Load Rating and Stay Within Limits

Before lifting any cable drum, verify the weight of the reel and compare it with the stand’s rated capacity. Exceeding the designed load can compromise the frame, spindle, or bearings.

Consider the following:

·The total mass of the cable plus reel core

·Whether both stands share the load evenly

·Safety margins for unusually heavy or long cable types

Adhering to these limits protects both the stand and the workers handling the drum.

2. Set Up Only on Stable, Level Ground

The stability of Cable Jack Stands relies heavily on the ground conditions. A level foundation prevents leaning or shifting when the reel is lifted.

Best practices include:

·Checking surface firmness before setup

·Avoiding soft soil or sloped terrain

·Using ground plates if the area is uneven

A firm and balanced base keeps the reel secure and significantly reduces the risk of accidental tipping.

3. Inspect the Equipment Before Every Use

Pre-operation inspection is essential. Even minor wear can affect performance when handling heavy reels.

Look for signs such as:

·Visible cracks in the stand frame

·Bent or worn spindles

·Rust on moving components

·Rollers that rotate unevenly

Conducting inspections regularly ensures problems are identified long before they affect job-site safety.

4. Raise the Cable Reel Gradually and Evenly

Lifting the drum should be a controlled, balanced process. Raising one side too quickly can misalign the reel or put stress on the spindle.

Follow these guidelines:

·Lift both sides in equal increments

·Watch for lateral movement during elevation

·Stop immediately if the reel becomes unstable

Even hydraulic or screw-type mechanisms require consistent movement to keep the drum centered.

5. Prevent Uncontrolled Reel Rotation

Once elevated, a cable drum must rotate only under deliberate control. Free-spinning reels can injure workers or damage expensive cable.

Ways to maintain controlled movement:

·Use braking devices where applicable

·Apply tension or drag during payout

·Make sure the spindle is seated securely

Controlled rotation ensures safe cable deployment while protecting the reel from sudden force.

6. Keep the Surrounding Area Clear of Obstructions

Maintaining a clean and organized workspace reduces risks significantly.

Ensure the following:

·Tools, cables, and debris are cleared away

·No personnel stand directly in the rotation path

·Workers maintain visual communication during payout

Clear surroundings allow operators to respond quickly if the reel shifts or requires adjustment.

7. Operate at a Steady Pace During Cable Unwinding

Abrupt pulling, especially with heavy machinery, can destabilize Cable Jack Stands. Smooth, steady unwinding minimizes stress on the equipment.

To maintain safe operation:

·Avoid jerking or rapid pulling

·Coordinate with the pulling team

·Monitor reel behavior continuously

A controlled pace protects the integrity of the stands and keeps the cable payout smooth.

8. Store the Equipment Correctly After Each Project

Proper storage preserves the strength and longevity of Cable Jack Stands, especially in regions with harsh weather.

After each use:

·Remove dirt and moisture

·Lubricate moving parts

·Store indoors or cover the equipment

·Re-inspect before next deployment

Well-maintained stands—especially those produced by a quality-focused Manufacturer with strong Production consistency—remain reliable even when used across multiple job sites or in bulk operations.

Conclusion

Using Cable Jack Stands correctly is essential for protecting both workers and equipment during heavy cable reel operations. By respecting load limits, ensuring stable ground conditions, carrying out inspections, and maintaining controlled lifting and payout, job-site safety can be significantly improved. When these stands come from a trusted Manufacturer with dependable Production quality and bulk supply capacity, the likelihood of safe and consistent performance increases even further. For any project that involves lifting or deploying cable drums, proper use of Cable Jack Stands remains a vital part of maintaining efficiency and safety on site.

References

GB/T 7714:Abdelhamid T S, Everett J G. Identifying root causes of construction accidents[J]. Journal of construction engineering and management, 2000, 126(1): 52-60.

MLA:Abdelhamid, Tariq S., and John G. Everett. "Identifying root causes of construction accidents." Journal of construction engineering and management 126.1 (2000): 52-60.

APA:Abdelhamid, T. S., & Everett, J. G. (2000). Identifying root causes of construction accidents. Journal of construction engineering and management, 126(1), 52-60.