Safety Tips When Using Glow Rods in Cable Installation

Author:jiujiu Release time:2025-12-18 20:39:38 Number of views:86order

Why Safety Matters When Working with Glow Rods

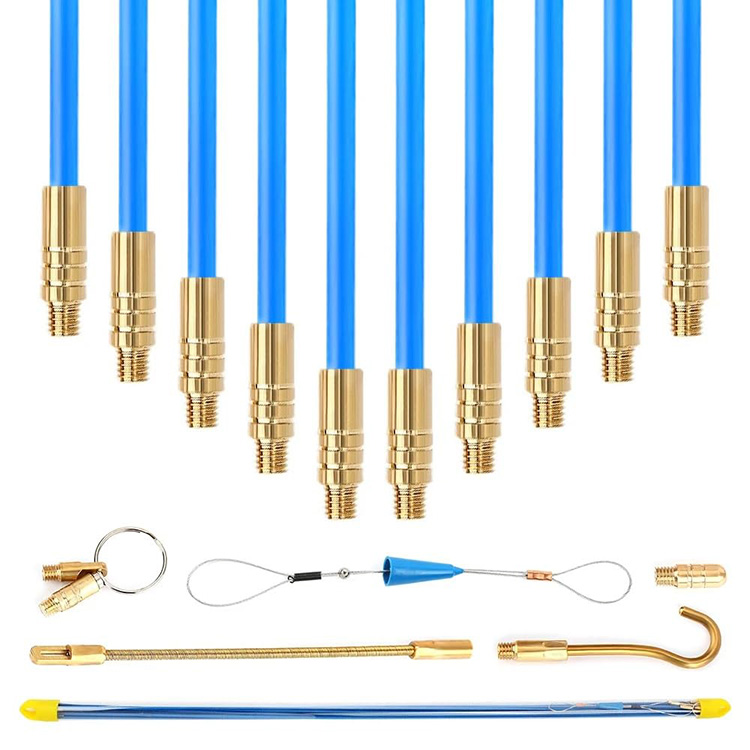

Glow rods are widely used in cable installation for routing wires through walls, conduits, ceilings, and hard-to-reach spaces. Their flexibility, strength, and visibility make them indispensable tools for electricians, data installers, and construction professionals.

However, improper handling of glow rods can lead to injuries, damaged cables, or costly rework. As a glow rods manufacturer with long-term experience in production and bulk supply for professional markets, understanding and promoting safe usage is just as important as manufacturing durable products.

This article provides practical safety tips to help professionals use glow rods efficiently while minimizing risks on job sites.

Understanding Glow Rods and Their Applications

Glow rods are typically made from fiberglass or composite materials and are designed to push or pull cables through confined spaces. Their glowing or high-visibility coating allows installers to track rod movement even in dark environments.

Common applications include:

·Electrical cable installation

·Network and fiber optic routing

·HVAC control wiring

·Industrial and commercial construction projects

While glow rods are engineered for strength and flexibility during production, safety still depends heavily on correct handling and proper working procedures.

Inspect Glow Rods Before Every Use

Before starting any cable installation task, always inspect glow rods carefully.

Key checks include:

·Surface cracks or splinters on fiberglass rods

·Loose threaded connectors between rod sections

·Excessive wear that could compromise structural integrity

Damaged glow rods can snap under pressure, posing a risk of hand injuries or eye damage. Professional manufacturers design glow rods for durability, but even high-quality production standards cannot compensate for misuse or prolonged wear.

Wear Proper Personal Protective Equipment (PPE)

Using glow rods without appropriate PPE increases the likelihood of injury.

Recommended protective equipment:

·Cut-resistant gloves to protect hands from splinters

·Safety glasses to shield eyes from debris or rod recoil

·Long sleeves when working in tight or overhead spaces

Fiberglass-based glow rods, even when produced under controlled manufacturing processes, can still release fine fibers if damaged. PPE should be considered a basic requirement on every job site.

Avoid Excessive Force During Cable Routing

One of the most common mistakes is applying excessive force when pushing glow rods through obstructions.

Safe practice tips:

·Advance rods slowly and steadily

·Stop immediately if resistance increases

·Never bend glow rods beyond their designed flexibility radius

Forcing glow rods can result in sudden breakage or loss of control. Experienced glow rods manufacturers design products to balance stiffness and flexibility, but no tool is indestructible under extreme stress.

Be Aware of Hidden Hazards in Installation Areas

Cable installation environments often contain unseen risks.

Potential hazards include:

·Live electrical wires

·Sharp metal edges inside conduits

·Moisture or chemical residues

Before inserting glow rods, verify that power sources are disconnected when possible. Even insulated glow rods should never be treated as electrical safety devices. Proper job-site assessment remains essential regardless of how advanced the production technology is.

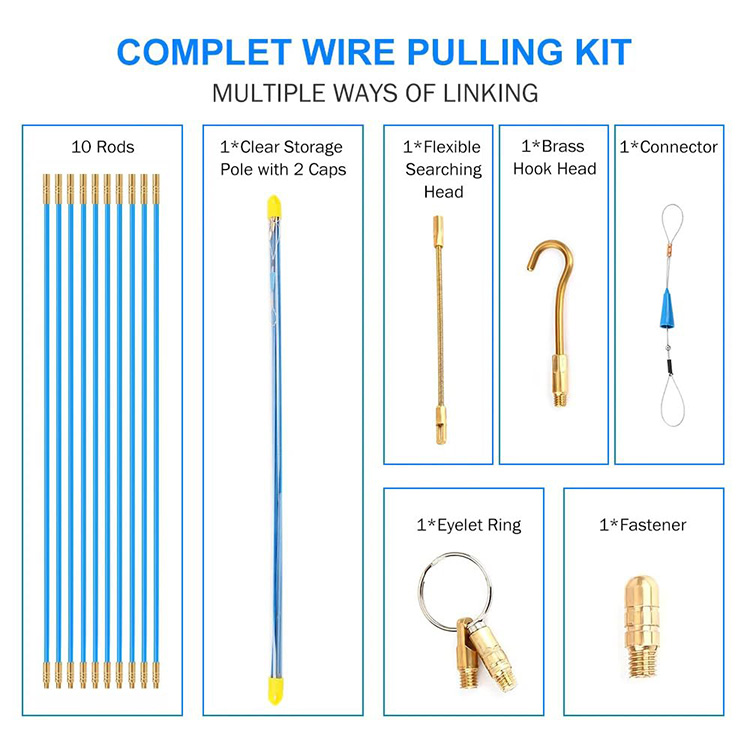

Use Compatible Accessories and Connectors

Glow rods are frequently used with hooks, pulling eyes, and leader attachments. Using incompatible or low-quality accessories can compromise safety.

Best practices include:

·Only using accessories designed for the rod diameter

·Ensuring threaded connections are fully tightened

·Avoiding makeshift or improvised attachments

Manufacturers that specialize in glow rods production and bulk supply typically test compatibility across accessories to ensure stable performance during cable pulls.

Store and Transport Glow Rods Correctly

Improper storage can reduce the lifespan and safety of glow rods.

Storage recommendations:

·Keep rods in protective cases or tubes

·Avoid prolonged exposure to direct sunlight or extreme heat

·Store rods straight to prevent permanent deformation

Proper storage preserves material integrity and ensures glow rods perform as intended during installation.

Training and Team Communication on Job Sites

Even high-quality glow rods can become hazardous tools if operators lack training.

Safety-focused teams should:

·Train workers on correct rod assembly and handling

·Establish clear communication when pulling cables

·Coordinate movements when working in pairs or confined spaces

Professional glow rods manufacturers often supply products globally in bulk, but safe outcomes ultimately depend on informed users applying best practices consistently.

Conclusion: Safety Starts with the Right Glow Rods and the Right Practices

Glow rods are essential tools in modern cable installation, offering efficiency and visibility in challenging environments. However, safety must always be a priority. By inspecting tools, wearing PPE, avoiding excessive force, and respecting installation hazards, professionals can significantly reduce risks.

From a manufacturing perspective, consistent production quality and reliable bulk supply ensure installers receive glow rods designed for demanding job-site conditions. From a user perspective, safe handling and proper techniques complete the equation.

By combining well-produced glow rods with disciplined safety practices, cable installation professionals can achieve both efficiency and long-term reliability on every project.

References

GB/T 7714:Antonini J M. Health effects of welding[J]. Critical reviews in toxicology, 2003, 33(1): 61-103.

MLA:Antonini, James M. "Health effects of welding." Critical reviews in toxicology 33.1 (2003): 61-103.

APA:Antonini, J. M. (2003). Health effects of welding. Critical reviews in toxicology, 33(1), 61-103.