The Essential Guide to Reel Jack Stands for Cable Handling

Author:jiujiu Release time:2025-11-10 10:03:26 Number of views:99order

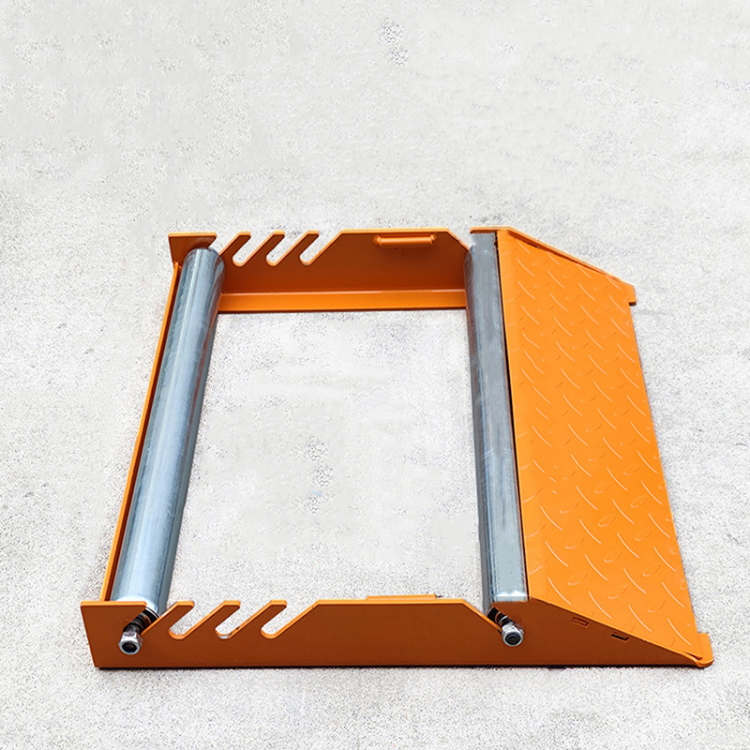

When handling long runs of heavy electrical or communication cables, stability and control are key. Among the most dependable tools on any job site are Reel Jack Stands — sturdy supports that lift and hold cable drums for smooth unwinding and installation.

As a Reel Jack Stand manufacturer in China providing bulk supply and OEM customization, we’ve worked with countless contractors and distributors who rely on this equipment daily. This article explains what Reel Jack Stands are, how they function, and what factors make one model superior to another.

1. Understanding Reel Jack Stands

Reel Jack Stands are mechanical lifting systems designed to elevate and secure cable reels during handling or installation. They allow the reel to spin freely, making it easier to pull out cable without tangles, twists, or strain.

A typical setup includes:

·Heavy-duty steel frames that provide strength and stability.

·Central spindles or axles that support the reel’s weight.

·Adjustable lifting systems, such as screw or hydraulic mechanisms.

·Wide bases or tripod supports for balance on uneven ground.

They are used across industries — from power transmission to data cabling — wherever precision and safety in cable payout are required.

2. Why Reel Jack Stands Are Important

Without Reel Jack Stands, unspooling large cables can be risky and inefficient. The stands bring structure and control to cable operations by:

·Enhancing safety: Prevents reels from tipping or rolling uncontrollably.

·Improving efficiency: Provides stable rotation for faster, smoother unwinding.

·Reducing manpower: Eliminates the need for multiple workers to manually roll reels.

·Protecting cables: Prevents abrasion and tangling during installation.

When sourced from a China manufacturer offering bulk supply, quality Reel Jack Stands can handle large-scale installations at a much lower overall cost.

3. How Reel Jack Stands Work

Operating a Reel Jack Stand is simple but highly effective:

1.Position two stands parallel on a level surface.

2.Insert the steel spindle through the reel’s center hole.

3.Lift the reel by turning the screw handle or activating the hydraulic jack.

4.Lock the stand securely and check balance.

5.Pull out cable smoothly while the reel rotates freely.

The design ensures consistent rotation and easy cable payout with minimal effort, improving both productivity and safety on-site.

4. Types of Reel Jack Stands

There are several types of Reel Jack Stands, each suited for specific reel sizes and environments:

·Manual Screw-Type Stands:

Economical and easy to control. Suitable for medium-weight reels and general electrical work.

·Hydraulic Jack Stands:

Use hydraulic pumps to raise large, heavy cable drums effortlessly. Perfect for utility and industrial installations.

·Portable Folding Stands:

Compact, lightweight designs ideal for quick setup and small field operations.

·Fixed-Base Industrial Stands:

Designed for workshops or warehouses where cable reels are regularly loaded, stored, and dispensed.

When selecting, balance load requirements with portability and lifting range.

5. Choosing the Right Reel Jack Stand

Selecting the right Reel Jack Stand depends on several key factors:

·Load capacity: Ensure the stand supports the full reel weight.

·Material quality: Choose steel or alloy structures with rust-resistant coating.

·Height adjustment: The wider the range, the more flexibility for various reel sizes.

·Ease of assembly: Quick setup saves time during fieldwork.

·Manufacturer reliability: A China factory offering bulk supply ensures consistent standards and factory-direct pricing.

Partnering directly with the manufacturer also allows for OEM customization, including color, branding, and capacity labeling.

6. Maintenance and Safe Operation

Routine maintenance extends the lifespan of your Reel Jack Stands and keeps operations safe. Here are best practices:

·Inspect bolts, welds, and moving parts before each use.

·Apply lubricants to screw threads or hydraulic joints periodically.

·Operate only on level, solid ground to avoid instability.

·Never exceed rated load capacity.

·Clean and store in dry conditions after use.

Following these steps ensures smooth, safe operation and compliance with workplace safety standards.

7. Advantages of Sourcing from a China Manufacturer

Working directly with a Reel Jack Stand manufacturer in China provides several competitive benefits:

·Bulk supply with strict quality control.

·OEM and ODM customization for branding and technical specifications.

·Competitive pricing through direct factory channels.

·Efficient global logistics and steady supply for long-term projects.

These advantages make Chinese factories preferred partners for global cable equipment suppliers and engineering contractors seeking both quality and cost-effectiveness.

Conclusion

In every professional cable installation project, Reel Jack Stands play a key role in ensuring safety, efficiency, and precision. Understanding their structure, operation, and types helps you make smarter equipment choices for long-term performance.

If you’re searching for Reel Jack Stands from a China manufacturer or need bulk supply for electrical or telecommunication projects, working directly with a professional factory ensures dependable quality, fair pricing, and reliable after-sales support — the foundation of successful cable handling.

References

GB/T 7714:Wurzelbacher S J, Lampl M P, Bertke S J, et al. The effectiveness of ergonomic interventions in material handling operations[J]. Applied ergonomics, 2020, 87: 103139.

MLA:Wurzelbacher, Steven J., et al. "The effectiveness of ergonomic interventions in material handling operations." Applied ergonomics 87 (2020): 103139.

APA:Wurzelbacher, S. J., Lampl, M. P., Bertke, S. J., & Tseng, C. Y. (2020). The effectiveness of ergonomic interventions in material handling operations. Applied ergonomics, 87, 103139.