Top Advantages of Fiberglass Fish Tape for Electrical Conduits

Author:jiujiu Release time:2025-11-13 11:17:57 Number of views:138order

When it comes to wiring projects, efficiency and safety go hand in hand. Among the many tools electricians depend on, fiberglass fish tape stands out as one of the most practical and secure choices for pulling wires through conduits.

As an experienced fiberglass fish tape manufacturer with dedicated production lines, we’ve seen how this simple yet powerful tool can dramatically improve workflow, reduce risks, and boost productivity in electrical installations. This article explores why fiberglass fish tape has become the preferred solution in conduit work across various industries.

1. Safe, Non-Conductive Design for Electrical Work

Electrical safety is a non-negotiable factor in any wiring job. Unlike traditional steel fish tapes, fiberglass fish tape is made from non-conductive composite material, meaning it won’t carry electric current. This eliminates the danger of electric shock when working near live circuits or energized panels.

The fiberglass core acts as an insulator, offering peace of mind to professionals who often need to fish wires in active environments. In addition, it meets strict safety standards, making it a reliable choice for construction, maintenance, and repair projects alike.

2. Superior Flexibility for Complex Conduit Layouts

Electrical conduits rarely follow straight paths. They twist, turn, and bend through walls, ceilings, and machinery. The flexibility of fiberglass fish tape allows electricians to guide wires smoothly through these paths without snagging or breaking.

The semi-rigid structure of fiberglass gives it enough push strength to cover long distances while maintaining just the right amount of bend to navigate curves. Combined with a smooth exterior coating, this flexibility helps minimize friction and protects cables from damage during pulling.

For electricians managing intricate conduit systems, this adaptability is a huge time-saver.

3. Lightweight, Durable, and Long-Lasting

One of the biggest benefits of fiberglass fish tape is its balance of weight and durability. Fiberglass is much lighter than steel yet extremely strong under tension. This makes it easier to carry and maneuver, even during extended installations.

It also resists cracking, corrosion, and surface wear, maintaining its pulling strength even after years of heavy use. For professionals handling multiple projects daily, the combination of low weight and high durability significantly reduces fatigue and tool replacement costs.

4. Resistant to Rust, Corrosion, and Harsh Environments

Electrical installations are often performed in damp basements, outdoor sites, or industrial settings where humidity and temperature changes are constant. Steel tapes may corrode or rust under such conditions — fiberglass won’t.

Because it’s chemically stable, fiberglass fish tape retains its strength and flexibility regardless of the environment. This makes it ideal for long-term use in underground conduits, tunnels, or marine applications.

Even when exposed to moisture, heat, or chemicals, fiberglass maintains its performance, ensuring consistent reliability in all working conditions.

5. Simple to Use and Maintain

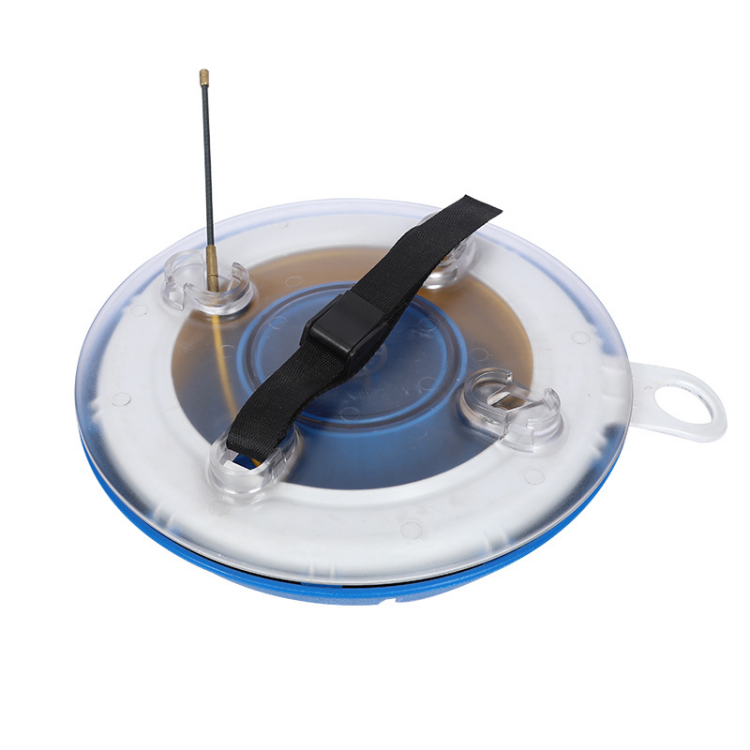

Fiberglass fish tape is not just safe and strong — it’s also easy to handle. Most models come in a compact reel that allows users to feed and retrieve the tape with minimal effort. The handle design provides excellent grip, allowing for controlled pulling even in tight spaces.

Maintenance is minimal: after use, simply wipe the tape clean, check for any surface wear, and store it properly in its case. There’s no need for lubrication or anti-rust treatment as with steel tapes. This simplicity makes fiberglass fish tape a go-to tool for both professionals and apprentices.

6. Excellent Visibility for Safer Operation

Another practical feature of fiberglass fish tape is its high-visibility color, typically bright yellow or orange. This enhances safety on job sites by making the tape easy to spot, even in low-light environments or crowded conduits.

Good visibility helps electricians monitor tape progress, prevent tangling, and improve precision when pulling multiple lines simultaneously. This detail might seem small, but it contributes significantly to a smoother workflow and safer job performance.

7. Economical in the Long Term

While fiberglass fish tape may cost slightly more upfront than metal versions, its durability and low maintenance make it a smart long-term investment. Electricians can rely on it for years without frequent replacements, and its resistance to rust or wear reduces overall tool expenses.

For large projects or contractors managing multiple crews, the ability to reuse tools across different sites translates into measurable cost efficiency.

8. Versatile Applications Across Industries

Beyond electrical work, fiberglass fish tape is useful for various cable routing applications, including:

·Communication and data cable installation

·Control wiring for automation systems

·Security and alarm wiring

·Lighting and low-voltage systems

Its non-conductive and flexible nature allows it to perform well in both residential and industrial settings, making it an essential multi-purpose wire pulling tool.

Choosing Quality from a Certified Manufacturer

Sourcing your tools from a trusted fiberglass fish tape manufacturer ensures consistent quality and reliable performance. A manufacturer with established production capability controls every stage — from material selection to final inspection — guaranteeing that each tape meets professional safety and durability standards.

We specialize in producing fiberglass fish tapes for electricians, builders, and maintenance engineers. Our products are available in multiple lengths and diameters to match different conduit sizes, and we support bulk supply for distributors and industrial buyers.

By partnering directly with the manufacturer, customers gain cost benefits, better product consistency, and assured technical support.

Conclusion

The fiberglass fish tape has become an indispensable tool for modern electrical conduit work. With its combination of safety, flexibility, corrosion resistance, and long-term durability, it outperforms metal alternatives in nearly every category.

As a professional fiberglass fish tape manufacturer with proven production strength and bulk supply capacity, we continue to deliver tools that meet the demands of electricians worldwide. Investing in high-quality fiberglass fish tape is not just about pulling wires — it’s about improving safety, efficiency, and reliability across every electrical project.

References

GB/T 7714:Ueng S K, Chang C C. Concealed Conduit Routing in Building Slabs[J]. Applied Sciences, 2023, 13(19): 10847.

MLA:Ueng, Shyh-Kuang, and Chun-Chieh Chang. "Concealed Conduit Routing in Building Slabs." Applied Sciences 13.19 (2023): 10847.

APA:Ueng, S. K., & Chang, C. C. (2023). Concealed Conduit Routing in Building Slabs. Applied Sciences, 13(19), 10847.