Understanding the Structure of Beetle Shaped Fish Tapes

Author:jiujiu Release time:2025-12-24 23:32:47 Number of views:124order

Why Structure Matters in Beetle Shaped Fish Tape Design

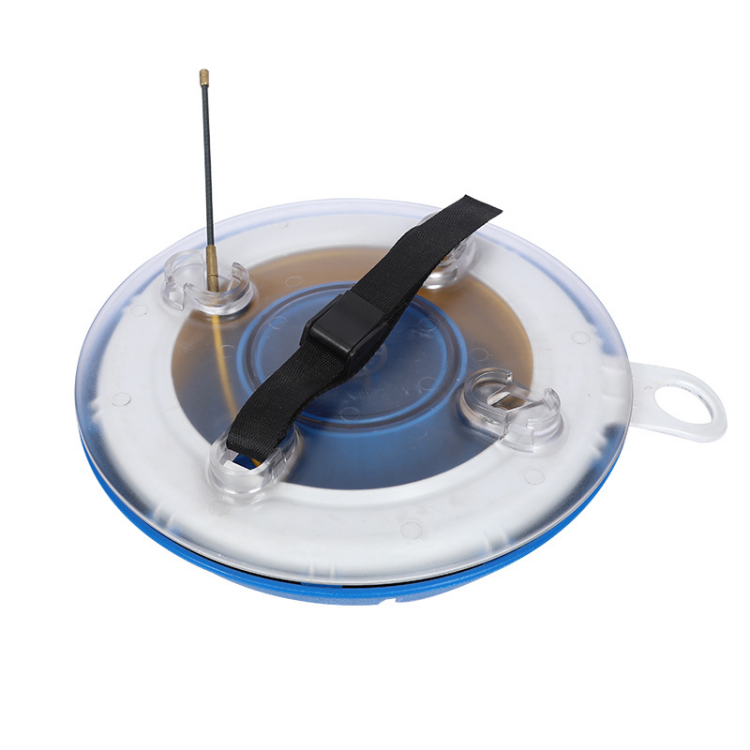

Beetle shaped fish tape has become increasingly popular in modern cable installation due to its compact form, improved handling, and enhanced maneuverability in confined spaces. Unlike traditional flat or round fish tapes, the beetle-inspired structure integrates multiple functional elements into a single, ergonomic design.

From a manufacturing standpoint, understanding the structure of beetle shaped fish tape is essential to achieving consistent performance during production and ensuring reliability in bulk supply for professional installers. This article provides a detailed breakdown of its structural components, material considerations, and functional advantages, helping users better understand why design plays such a critical role in real-world applications.

What Is a Beetle Shaped Fish Tape?

A beetle shaped fish tape refers to a cable pulling tool designed with a compact, enclosed housing that resembles the profile of a beetle. The housing protects the internal tape while offering improved grip, balance, and control during operation.

Common applications include:

·Electrical wiring installation

·Data and communication cable routing

·Retrofit projects in walls, ceilings, and conduits

·Commercial and industrial construction

While the external form attracts attention, it is the internal structure—refined through controlled production processes—that determines long-term usability and safety.

Core Structural Components of Beetle Shaped Fish Tapes

Reinforced Outer Housing

The outer shell of a beetle shaped fish tape is typically manufactured from high-strength polymer or composite materials. This housing serves several purposes:

·Protects the internal tape from impact and contamination

·Maintains compact dimensions for confined spaces

·Provides ergonomic handling during extended use

Manufacturers design the housing to withstand repeated job-site stress, especially when products are produced in large batches for professional markets.

Internal Tape Mechanism

At the core of the structure is the fish tape itself, commonly made from fiberglass, steel, or reinforced composite materials. The internal tape is engineered to balance flexibility and stiffness, allowing it to navigate bends without buckling.

Key structural considerations include:

·Uniform cross-section for consistent pushing force

·Smooth surface finish to reduce friction inside conduits

·Controlled stiffness achieved during production

The precision of this internal component directly reflects manufacturing quality standards.

Reel and Retraction System

Beetle shaped fish tapes often feature an integrated reel or guided retraction system. This structural element ensures:

·Smooth extension and retraction of the tape

·Reduced twisting or tangling during operation

·Better control when working in tight or overhead environments

From a production perspective, consistent alignment of the reel system is essential, particularly for bulk supply where uniform performance is expected across all units.

Leader Tip and Connection Interface

The leader tip is a small but critical structural component. It connects the fish tape to cables, pulling grips, or accessories.

Typical design features include:

·Reinforced tip geometry to prevent bending

·Secure threading or crimped connections

·Compatibility with standard cable-pulling accessories

Manufacturers test leader tips extensively during production to ensure reliability under pulling tension.

Material Selection and Structural Integrity

Material choice plays a vital role in the overall structure of beetle shaped fish tape. High-quality materials contribute to:

·Resistance to wear and fatigue

·Improved safety in electrical environments

·Consistent performance across temperature variations

Fiberglass-based tapes are often favored for their non-conductive properties, while composite housings provide strength without unnecessary weight. Manufacturers focused on long-term bulk supply prioritize material stability to reduce variation between production batches.

Ergonomic Design and User Interaction

Beyond internal mechanics, the beetle shaped structure is optimized for user comfort and control.

Ergonomic features may include:

·Contoured grip surfaces

·Balanced weight distribution

·Low-profile housing for one-handed operation

These design elements reduce user fatigue and enhance precision, especially during repetitive cable installation tasks. From a structural standpoint, ergonomics are not cosmetic—they are engineered outcomes of thoughtful production design.

Structural Advantages in Confined Installation Spaces

The compact structure of beetle shaped fish tape offers clear advantages in restricted environments.

Benefits include:

·Easier navigation through narrow openings

·Reduced snagging inside conduits

·Better visibility and control during routing

These advantages stem directly from the internal and external structure working together as a unified system, rather than from any single component alone.

Quality Control in Manufacturing and Production

Producing beetle shaped fish tape at scale requires strict quality control across multiple stages:

·Material inspection

·Housing molding accuracy

·Tape tension and alignment testing

·Final assembly verification

Manufacturers supplying bulk quantities rely on standardized production processes to ensure every unit meets performance expectations. Structural consistency is essential for maintaining trust among professional users.

Conclusion: Structure as the Foundation of Performance

The effectiveness of beetle shaped fish tape is rooted in its structure. From the reinforced housing and internal tape mechanism to ergonomic design and material selection, every element contributes to reliable performance in demanding cable installation environments.

When beetle shaped fish tape is developed through controlled manufacturing processes and supplied in bulk for professional use, its structural advantages become even more apparent. Understanding these design principles allows users to select tools that deliver efficiency, safety, and long-term value on site.

References

GB/T 7714:Organización Internacional de Normalización. Ergonomics of Human-system Interaction: Human-centred Design for Interactive Systems[M]. ISO, 2010.

MLA:Organización Internacional de Normalización. Ergonomics of Human-system Interaction: Human-centred Design for Interactive Systems. ISO, 2010.

APA:Organización Internacional de Normalización. (2010). Ergonomics of Human-system Interaction: Human-centred Design for Interactive Systems. ISO.