What Is a Duct Rodder and How It Works | Manufacturer’s Guide

Author:jiujiu Release time:2025-11-15 12:24:16 Number of views:63order

When electricians, telecom engineers, or contractors need to guide cables through underground conduits or wall ducts, they depend on one essential tool — the Duct Rodder. Sometimes called a conduit rod or fish tape, this flexible yet strong device makes cable installation faster, safer, and more accurate.

In this article, we’ll explore what a Duct Rodder is, how it operates, and why it’s a preferred choice among professional installers and manufacturers who focus on efficient large-scale production and reliable cable pulling solutions.

1. Understanding the Duct Rodder

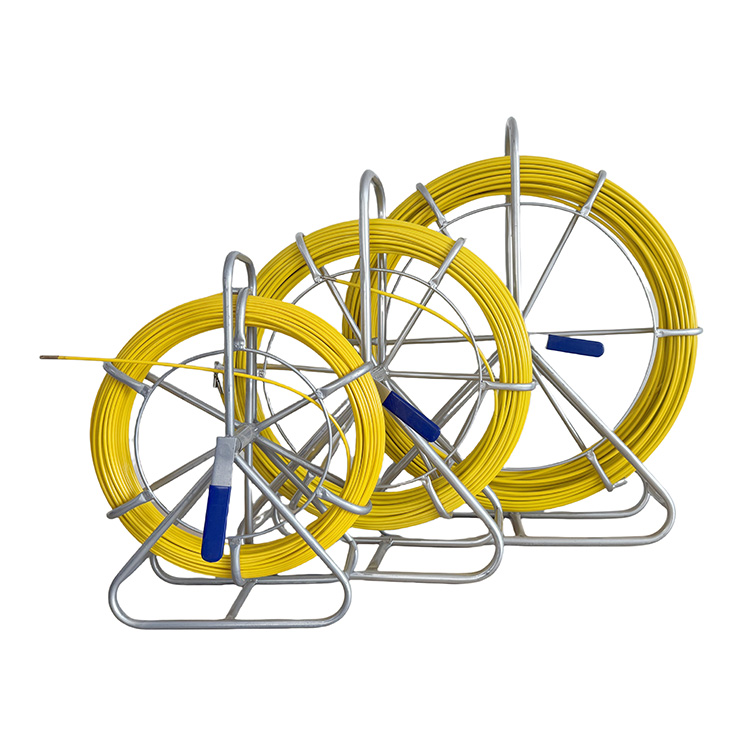

A Duct Rodder is a semi-rigid rod made from high-strength fiberglass or composite materials. It’s designed to push or pull cables through pipes, conduits, and underground ducts without damaging the insulation or surrounding structure.

Typically mounted on a durable steel or aluminum frame, it’s equipped with a pulling eye or threaded head at the tip, allowing it to connect easily with cable grips, ropes, or pulling accessories.

Its flexibility and rigidity are carefully balanced — flexible enough to navigate bends, yet firm enough to push over long distances.

2. How Does a Duct Rodder Work?

The working process is straightforward but effective:

1.Insertion: The Duct Rodder is fed into a duct or conduit manually or with a rotating reel.

2.Navigation: Thanks to its fiberglass core, the rod smoothly passes through curves or narrow paths while maintaining directional control.

3.Cable Attachment: Once it reaches the other end, a cable or wire rope is attached to its pulling head.

4.Retrieval: The operator then reels the Duct Rodder back, pulling the cable through the duct efficiently.

Many models include a copper core or traceable wire, which allows users to detect the rod’s position underground using a signal transmitter — an important feature in telecom or civil engineering projects.

3. Materials and Construction

High-quality Duct Rodders are typically made from:

·Fiberglass core: provides high tensile strength and flexibility.

·Polyethylene (PE) coating: protects against wear, UV exposure, and moisture.

·Brass or steel fittings: ensure secure attachment and corrosion resistance.

These materials allow for continuous use even in challenging environments like underground systems, cable tunnels, and industrial installations.

4. Key Advantages of Using a Duct Rodder

a. Time Efficiency

A Duct Rodder dramatically reduces installation time compared to manual cable feeding. Its smooth coating minimizes friction, allowing long-distance cable pulling in a single run.

b. Safety and Reliability

The non-conductive fiberglass rod prevents electrical hazards, making it safe for use near live circuits or power lines.

c. Long Service Life

With proper maintenance, a quality Duct Rodder can withstand thousands of operations without losing elasticity or surface smoothness.

d. Easy Storage and Mobility

The frame is designed for easy transport and quick retraction, ideal for field use or workshop organization.

5. Choosing the Right Duct Rodder

When selecting a Duct Rodder, consider:

·Rod diameter and length: match the conduit size and distance.

·Flexibility: suitable for straight or curved ducts.

·Traceability: choose a rod with an embedded copper wire if detection is needed.

·Frame design: strong structure with smooth rolling reel for effortless operation.

Reliable manufacturers often provide customized options — different sizes, connector types, and coating colors — to meet diverse industrial requirements. Large-scale production ensures consistent quality and timely supply for bulk orders.

6. Maintenance Tips

To extend the life of your Duct Rodder, follow these best practices:

·Clean the rod after each use to remove sand or mud.

·Inspect for cracks, surface wear, or connector looseness.

·Lubricate the reel and fittings periodically.

·Store it in a dry, shaded place to prevent UV damage.

Routine care not only improves safety but also guarantees optimal performance during every pull.

7. Applications in Different Industries

The Duct Rodder is widely used across:

·Electrical installations for pulling power cables;

·Telecommunication networks for fiber optic deployment;

·Civil engineering for conduit maintenance;

·Industrial production facilities where regular wiring upgrades are required.

Its versatility makes it indispensable for both contractors and infrastructure service providers.

Conclusion

A Duct Rodder may appear simple, but it’s a highly engineered tool that combines flexibility, durability, and safety to make cable routing more efficient. Electricians and network technicians rely on it every day to guide cables through ducts quickly and safely.

When sourced from a professional manufacturer with proven production capacity, you can expect precise design, consistent quality, and bulk availability — all essential for demanding electrical or communication projects.

For reliability, performance, and long-term value, the Duct Rodder remains an essential investment in every professional installer’s toolkit.

References

GB/T 7714:Attia M M, Ahmed O, Kobesy O, et al. Behavior of FRP rods under uniaxial tensile strength with multiple materials as an alternative to steel rebar[J]. Case Studies in Construction Materials, 2022, 17: e01241.

MLA:Attia, Mohamed M., et al. "Behavior of FRP rods under uniaxial tensile strength with multiple materials as an alternative to steel rebar." Case Studies in Construction Materials 17 (2022): e01241.

APA:Attia, M. M., Ahmed, O., Kobesy, O., & Malek, A. S. (2022). Behavior of FRP rods under uniaxial tensile strength with multiple materials as an alternative to steel rebar. Case Studies in Construction Materials, 17, e01241.