What Is Fiberglass Fish Tape and Why Electricians Use It

Author:jiujiu Release time:2025-11-13 11:17:57 Number of views:150order

In the electrical trade, having the right tools can make or break the job. One such essential tool is the fiberglass fish tape — a sturdy, flexible, and non-conductive line designed to guide wires through tight spaces. From small residential jobs to complex industrial wiring systems, electricians rely on this tool for fast and safe cable routing.

As a professional fiberglass fish tape manufacturer with strong production capacity, we understand the value of dependable materials and precision design. This article explains what fiberglass fish tape is, how it functions, and why it has become a standard in the electrical industry.

What Exactly Is a Fiberglass Fish Tape?

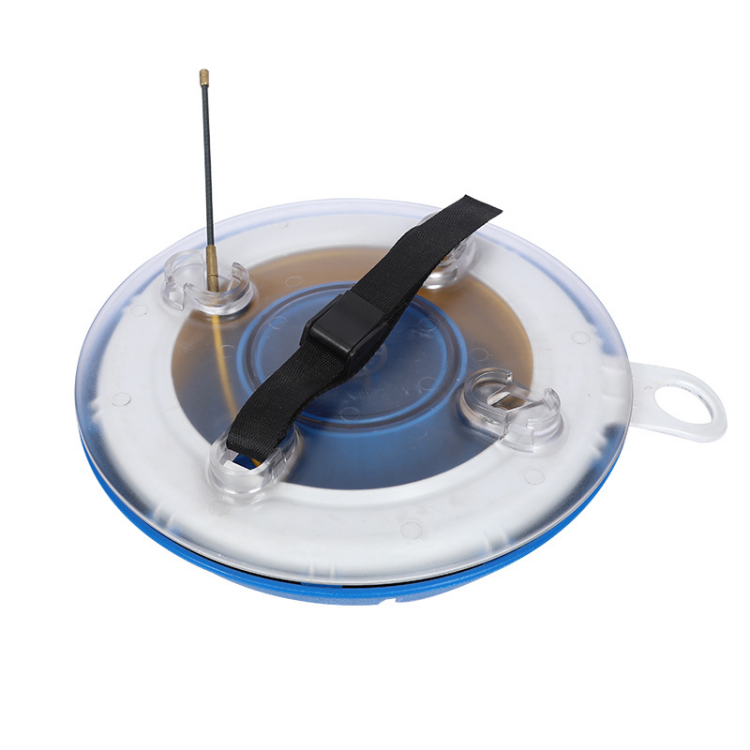

A fiberglass fish tape is a long, flat strip made from reinforced fiberglass composites, typically wound inside a plastic case or reel. Electricians use it to thread or “fish” wires through conduits, walls, and ceilings where direct access is difficult.

Unlike traditional steel fish tapes, fiberglass versions are non-conductive, meaning they can be safely used in areas with live electrical circuits without risking short circuits or shocks. This makes them especially useful in high-voltage or maintenance environments.

Main Features:

·Safe and non-conductive: Ideal for work near energized circuits.

·High flexibility: Easily navigates conduit bends and corners.

·Lightweight but strong: Can withstand tension while remaining easy to handle.

·Smooth surface: Reduces wire friction during pulling.

·Rust-resistant: Will not corrode or degrade under humidity or outdoor use.

How Electricians Use Fiberglass Fish Tape

Using a fiberglass fish tape is straightforward but requires steady handling for best results. The tape is inserted into a conduit until it reaches the desired exit point. A wire or cable is then fastened to the end of the tape, and the electrician pulls it back through the conduit.

This process keeps the cable safe from kinks or abrasions and minimizes installation time, especially on long wire runs.

Typical operation steps include:

1.Feed the fiberglass fish tape into the conduit carefully.

2.Once it reaches the endpoint, secure the wire using electrical tape.

3.Pull the tape back slowly to draw the wire through.

4.Detach the wire and rewind the tape into its reel for storage.

With a bit of technique, electricians can handle complex conduit networks efficiently using fiberglass fish tape.

Why Electricians Choose Fiberglass Over Metal

Fiberglass fish tapes have several advantages that make them a go-to option in electrical and communication installations.

1.Enhanced Safety:

Fiberglass does not conduct electricity, providing added protection when working around active circuits.

2.Superior Flexibility:

The tape can bend around corners and pass through narrow conduits without snapping.

3.Corrosion Resistance:

Unlike steel, fiberglass does not rust, ensuring consistent performance even in humid environments.

4.Ease of Use:

Its light weight makes it simple to carry and operate on long installations.

5.Long-Term Durability:

Fiberglass tapes maintain strength and elasticity after repeated use, offering excellent return on investment for professionals.

These qualities make fiberglass fish tape an indispensable tool for electricians who value both safety and efficiency.

Common Uses of Fiberglass Fish Tape

While primarily used by electricians, fiberglass fish tape also finds applications in various fields:

·Running electrical wires through conduits and walls in homes or offices.

·Installing network cables and communication lines.

·Pulling control wires in industrial automation systems.

·Routing power cables in construction and renovation projects.

Its non-conductive property and tensile strength make it versatile enough for both light-duty residential jobs and heavy commercial installations.

Maintenance and Handling Tips

To ensure long-lasting performance from your fiberglass fish tape, follow a few simple care guidelines:

·Clean after each use: Wipe off dust, grease, or debris to preserve the surface finish.

·Avoid excessive bending: Sharp bends can weaken the tape over time.

·Inspect regularly: Check the pulling head and reel for cracks or wear.

·Store properly: Keep the tape coiled in its case to prevent deformation.

·Use gentle pulling pressure: Avoid forcing it through blocked conduits to prevent breakage.

Proper maintenance keeps your tool dependable and ready for any wiring task.

Choosing Quality from a Trusted Manufacturer

Selecting fiberglass fish tape from a certified manufacturer ensures better quality control and consistency. A company with dedicated production lines and engineering expertise can balance the right strength, flexibility, and insulation performance needed for demanding work environments.

We produce fiberglass fish tapes in multiple lengths and diameters to suit different applications. Our bulk supply options serve electricians, distributors, and industrial buyers who require durable, safety-tested wire pulling tools.

Conclusion

The fiberglass fish tape is more than a simple wire-pulling accessory — it’s a safety tool that improves efficiency and protects electricians on the job. Its combination of non-conductivity, flexibility, and longevity makes it the preferred solution for professional electrical installations worldwide.

As an experienced fiberglass fish tape manufacturer with proven production and bulk supply capacity, we deliver high-performance tools designed to meet strict quality and safety standards. Investing in quality fiberglass fish tape not only improves work efficiency but also ensures long-term reliability across every project.

References

GB/T 7714:Jaya T, Michalak B, Radke M, et al. Industrial Cabling in Constrained Environments: a Practical Approach and Current Challenges[J]. arXiv preprint arXiv:2404.10829, 2024.

MLA:Jaya, Tanureza, et al. "Industrial Cabling in Constrained Environments: a Practical Approach and Current Challenges." arXiv preprint arXiv:2404.10829 (2024).

APA:Jaya, T., Michalak, B., Radke, M., & Haninger, K. (2024). Industrial Cabling in Constrained Environments: a Practical Approach and Current Challenges. arXiv preprint arXiv:2404.10829.