Essential Tools Every Cable Pulling Kit Should Have

Author:jiujiu Release time:2026-01-22 10:38:52 Number of views:95order

Why a Complete Cable Pulling Kit Matters

A Cable Pulling Kit is a fundamental solution for installing electrical cables, communication lines, and industrial wiring systems efficiently and safely. Whether used in construction sites, utility projects, or industrial facilities, a well-equipped cable pulling kit ensures smoother operations, reduced labor effort, and minimized cable damage.

From a manufacturing and production perspective, cable pulling kits are designed to support repeated use, standardized workflows, and bulk supply requirements. Factory-level production focuses on durability, compatibility, and performance consistency—qualities essential for professional cable installation environments.

Understanding the essential tools included in a cable pulling kit helps users select reliable solutions that meet both operational and industrial-scale needs.

What Is a Cable Pulling Kit?

A Cable Pulling Kit is a collection of tools designed to guide, pull, support, and protect cables during installation. These kits are commonly used for:

·Electrical conduit installations

·Underground cable routing

·Industrial wiring projects

·Utility and infrastructure construction

Professional-grade cable pulling kits are typically manufactured under controlled production processes to ensure uniform quality, making them suitable for large-volume supply and long-term use.

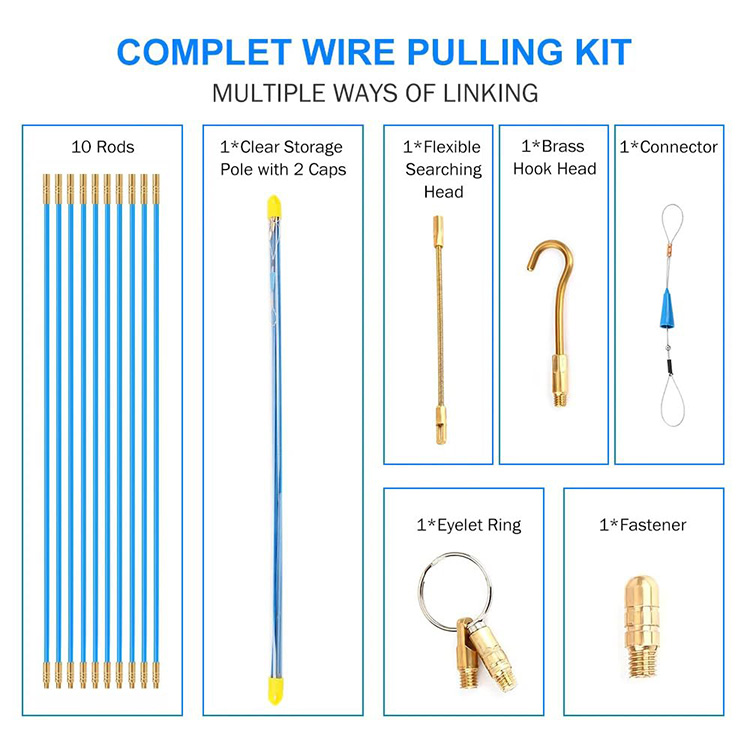

Core Components of a Cable Pulling Kit

1. Cable Pulling Rope or Line

The pulling rope is the backbone of any cable pulling kit. It transmits pulling force from the operator to the cable.

Key characteristics include:

·High tensile strength

·Low stretch under load

·Smooth surface to reduce friction

Manufacturers often produce pulling lines using synthetic fibers or reinforced materials to maintain strength and reliability across repeated installations.

2. Pulling Grips or Cable Socks

Pulling grips securely attach the pulling rope to the cable. They distribute force evenly around the cable jacket, reducing the risk of damage.

Common types:

·Single-eye pulling grips

·Double-weave grips

·Closed-end grips

In factory production, grip sizing and weave consistency are critical to ensure compatibility with standard cable diameters.

3. Swivel Connectors

Swivels prevent twisting during cable pulls, which is especially important in long or curved conduit runs.

Benefits include:

·Reduced cable torsion

·Improved pulling efficiency

·Longer cable lifespan

Swivel components are typically precision-machined during production to maintain smooth rotation under load.

4. Conduit Guides and Rollers

Guides and rollers help redirect cables through corners, bends, and entry points.

Advantages:

·Lower pulling friction

·Reduced surface wear on cables

·Improved safety during installation

Industrial cable pulling kits often include heavy-duty rollers designed for high-load and repeated use in factory-supported applications.

5. Lubricant Applicators

Cable pulling lubricants reduce friction between the cable and conduit walls. Applicators ensure even distribution during installation.

Lubrication tools help:

·Lower pulling force

·Prevent cable jacket damage

·Improve installation speed

In large-scale production environments, standardized lubricant compatibility is considered during kit assembly.

6. Measuring and Tension Monitoring Tools

Accurate measurement is essential for controlled cable installation.

These tools may include:

·Measuring tapes

·Tension indicators

·Load monitoring devices

Manufacturers integrate these components to support consistent installation quality across multiple projects.

7. Storage and Transport Case

A durable case keeps all components organized and protected.

Key features:

·Impact-resistant construction

·Clearly labeled compartments

·Easy transport for job sites

From a factory supply standpoint, standardized packaging supports bulk shipping and inventory management.

Why Manufacturers Design Complete Cable Pulling Kits

From a production and factory perspective, offering a complete Cable Pulling Kit ensures:

·Tool compatibility across applications

·Reduced setup time for installers

·Consistent performance in large-scale projects

Manufacturers focus on modular design and quality control so that kits meet professional standards and support long-term industrial use.

How to Choose the Right Cable Pulling Kit

When selecting a cable pulling kit, consider:

·Maximum pulling load

·Cable diameter compatibility

·Project environment (indoor, outdoor, underground)

·Frequency of use

Sourcing from a manufacturer with stable production capacity and bulk supply capabilities ensures consistency and reliability for ongoing projects.

Maintenance Tips for Long-Term Performance

To extend the life of your cable pulling kit:

·Inspect ropes and grips regularly

·Clean rollers and swivels after use

·Store tools in a dry, protected environment

·Replace worn components promptly

Proper maintenance supports safer operation and preserves factory-grade performance.

Conclusion: The Value of a Well-Equipped Cable Pulling Kit

A professional Cable Pulling Kit combines carefully selected tools that work together to improve efficiency, safety, and installation quality. From pulling ropes and grips to swivels and rollers, each component plays a vital role in successful cable installation.

For users requiring consistent quality and long-term supply, choosing solutions developed through controlled manufacturing and large-scale production processes is essential. As infrastructure and industrial projects continue to grow, factory-produced cable pulling kits will remain a key solution for reliable cable installation worldwide.

References

GB/T 7714:Williams J A, Ostermann P L, Samm R W. Underground Transmission Systems Reference Book[J]. EPRI Underground Transmission Program Electrical Systems Division, 1992.

MLA:Williams, J. A., P. L. Ostermann, and R. W. Samm. "Underground Transmission Systems Reference Book." EPRI Underground Transmission Program Electrical Systems Division (1992).

APA:Williams, J. A., Ostermann, P. L., & Samm, R. W. (1992). Underground Transmission Systems Reference Book. EPRI Underground Transmission Program Electrical Systems Division.