How to Choose the Best Beetle Shaped Fish Tape for Your Work

Author:jiujiu Release time:2026-02-09 22:56:18 Number of views:112order

The Beetle Shaped Fish Tape has become a popular tool for modern cable routing in electrical, telecommunications, and industrial installation projects. Designed for flexibility, control, and durability, it helps professionals guide wires smoothly through conduits, walls, ceilings, and narrow pathways. Compared with traditional straight fish tapes, the beetle-shaped structure offers better handling and directional stability.

With advanced manufacturer production systems and factory batch supply capability, today’s beetle shaped fish tape is no longer a simple strip of material. It is a precision-engineered product that combines optimized materials, structural design, and surface treatment. Choosing the right beetle shaped fish tape for your work can significantly improve efficiency, safety, and long-term performance.

This guide explains what to look for when selecting the best beetle shaped fish tape for your specific project needs.

What Is a Beetle Shaped Fish Tape?

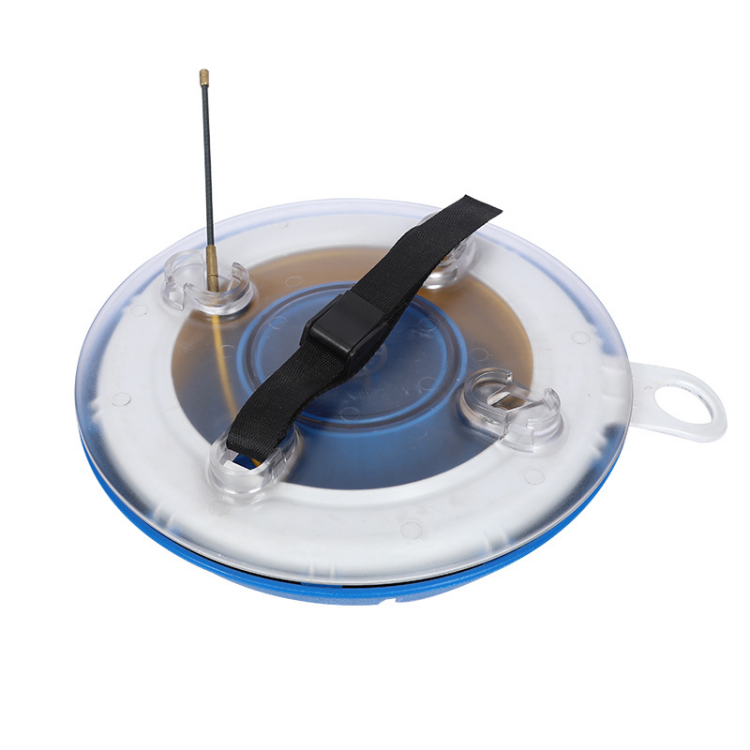

A beetle shaped fish tape is a cable guiding tool designed with a compact, curved, and ergonomic profile that resembles the form of a beetle. This design improves grip, balance, and push control during cable feeding.

A high-quality Beetle Shaped Fish Tape provides:

·Controlled stiffness for pushing

·Smooth flexibility for bends

·Lightweight handling

·Stable directional performance

Through professional factory production, the shape, thickness, and reinforcement layers are carefully formed to maintain consistent behavior across long conduit runs.

Material Selection Matters

Material determines how the beetle shaped fish tape performs under load, bending, and environmental exposure. Most advanced models use reinforced polyester, fiberglass, or composite polymers.

When choosing a Beetle Shaped Fish Tape, consider:

·Non-conductive properties for electrical safety

·High tensile strength for pulling cables

·Resistance to moisture and chemicals

·Fatigue resistance under repeated use

In modern manufacturer production, raw materials are formulated and processed to balance stiffness and flexibility. Composite structures allow the tape to transmit force efficiently while still navigating tight curves.

Size, Width, and Length Options

The dimensions of a beetle shaped fish tape directly affect usability.

Important factors include:

·Narrow width for tight or complex bends

·Wider profiles for long straight conduit runs

·Suitable length for project scale

A longer Beetle Shaped Fish Tape is ideal for commercial or industrial jobs, while shorter lengths suit residential wiring.

Through standardized factory batch supply, different widths and lengths are produced consistently, ensuring predictable performance from one project to another.

Stiffness and Flexibility Balance

One of the most important characteristics of a beetle shaped fish tape is how it balances rigidity and bendability.

If it is too flexible, it buckles. If it is too stiff, it struggles with corners.

An engineered Beetle Shaped Fish Tape offers:

·Longitudinal rigidity for pushing power

·Lateral flexibility for navigating curves

·Torsional stability to avoid twisting

During manufacturer production, fiber orientation and layer structure are controlled to fine-tune mechanical behavior. Factory testing verifies bending radius and push distance before batch delivery.

Surface Finish and Friction Control

Surface quality affects how smoothly the fish tape moves through conduits.

Look for features such as:

·Smooth outer coating

·Abrasion resistance

·Low-friction treatment

·Uniform thickness

Professional factory production applies surface coatings that reduce friction against metal, PVC, and concrete conduits. This helps the Beetle Shaped Fish Tape glide efficiently while protecting cable insulation from damage.

Tensile Strength and Load Capacity

Cable pulling requires dependable tensile performance.

A reliable Beetle Shaped Fish Tape should provide:

·High breaking strength

·Minimal permanent elongation

·Stable recovery after load release

In advanced manufacturer production systems, tensile and fatigue tests ensure each batch meets working load standards. This consistency allows professionals to use beetle shaped fish tape safely for bundled or heavy cables.

Environmental Adaptability

Different projects face different conditions. The beetle shaped fish tape must perform in both indoor and outdoor environments.

Consider resistance to:

·Moisture and humidity

·Temperature changes

·Mild chemicals

·UV exposure

Through optimized factory production, stabilizers and additives are integrated into the material structure to maintain performance across varying jobsite conditions.

This ensures long-term durability of the Beetle Shaped Fish Tape even under repeated exposure.

Safety and Ergonomic Design

The beetle shape is not only aesthetic, it improves handling and safety.

Advantages include:

·Better grip control

·Reduced recoil energy

·Lightweight operation

·Smooth edges to prevent cable damage

During manufacturer production, ergonomic shaping and surface inspection help ensure user comfort and operational safety in daily cable installation tasks.

Importance of Manufacturer and Factory Production

Choosing a beetle shaped fish tape is not just about the tool, but also about how it is made. A professional manufacturer production process includes:

·Raw material formulation

·Structural reinforcement control

·Surface coating application

·Mechanical performance testing

With organized factory batch supply, large quantities of beetle shaped fish tape can be delivered with uniform quality for contractors and industrial users.

Factory production also supports customization of stiffness, length, and profile for different cable routing requirements.

Typical Applications

Because of its engineered structure, the Beetle Shaped Fish Tape is widely used in:

·Electrical conduit installation

·Telecommunications cabling

·Commercial construction

·Industrial automation

·Maintenance and retrofit projects

The beetle-shaped design improves control and efficiency when routing cables through complex pathways.

Maintenance Tips for Long-Term Use

To maximize service life:

·Clean after each job

·Avoid sharp edges

·Store in a dry place

·Inspect surface coating

·Rewind properly

Manufacturer guidelines usually accompany factory-produced beetle shaped fish tape to preserve performance across repeated cycles.

Conclusion

The Beetle Shaped Fish Tape is a specialized, high-performance tool for modern cable installation. Choosing the best one requires attention to material quality, size, stiffness balance, surface finish, tensile strength, and environmental adaptability.

With advanced manufacturer production systems and factory batch supply capability, today’s beetle shaped fish tape delivers consistent performance, safety, and durability for professional applications. By selecting the right Beetle Shaped Fish Tape, users can improve installation efficiency, protect cables, and ensure reliable results across every project.

References

GB/T 7714:Wurzelbacher S J, Lampl M P, Bertke S J, et al. The effectiveness of ergonomic interventions in material handling operations[J]. Applied ergonomics, 2020, 87: 103139.

MLA:Wurzelbacher, Steven J., et al. "The effectiveness of ergonomic interventions in material handling operations." Applied ergonomics 87 (2020): 103139.

APA:Wurzelbacher, S. J., Lampl, M. P., Bertke, S. J., & Tseng, C. Y. (2020). The effectiveness of ergonomic interventions in material handling operations. Applied ergonomics, 87, 103139.