Maintaining and Cleaning Fiberglass Fish Tape for Longevity

Author:jiujiu Release time:2026-02-22 13:09:24 Number of views:111order

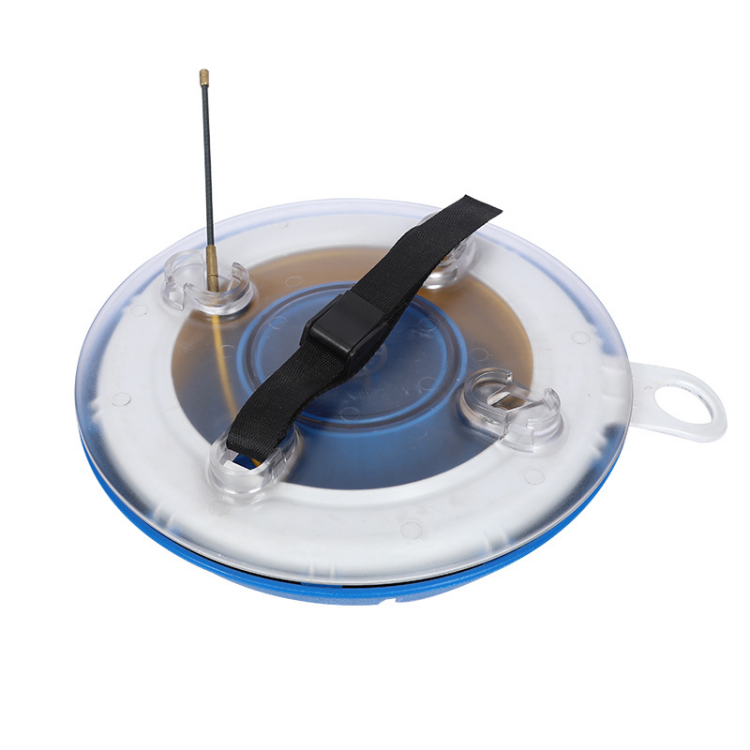

Fiberglass Fish Tape plays a crucial role in electrical and cable routing projects. Its flexibility and strength make it ideal for navigating conduits and confined spaces. However, even high-performance tools require proper upkeep. Maintaining Fiberglass Fish Tape correctly helps preserve flexibility, prevent surface damage, and ensure reliable pulling performance over time.

This article explains how to clean, inspect, and store Fiberglass Fish Tape to maximize its durability.

The Importance of Regular Maintenance

Although fiberglass is corrosion-resistant and strong, job site environments can be harsh. Dirt, debris, moisture, and construction residue gradually affect the tool’s surface and structural integrity.

Neglecting maintenance may result in:

·Stiff operation

·Surface cracking

·Reduced pulling strength

·Connector corrosion

·Shortened product lifespan

Routine care ensures smoother performance and fewer replacements.

Effective Cleaning Methods

Immediate Surface Cleaning

After each use, wipe the tape with a dry cloth. This prevents dust and debris from accumulating. For tougher dirt, lightly dampen the cloth and clean along the tape’s length.

Avoid soaking the tape directly in water.

Deep Cleaning for Heavy Residue

When exposed to grease or mud:

1.Prepare warm water with mild soap

2.Use a soft cloth to gently clean the surface

3.Remove all soap residue

4.Dry thoroughly before storage

Stay away from aggressive chemicals that could damage the fiberglass coating.

Inspection During Cleaning

Cleaning time is ideal for inspection. Check for:

·Surface splintering

·Worn protective layers

·Damaged pulling heads

·Signs of rust

Addressing minor wear early prevents performance decline.

Proper Drying and Moisture Control

Water exposure can lead to hidden damage if not managed properly. Always:

·Allow complete air drying

·Keep away from prolonged sun exposure

·Store only after fully dry

Moisture trapped in the reel housing can accelerate corrosion of metal components.

Lubrication Tips

Occasional light lubrication can improve usability. A small amount of silicone-based lubricant helps reduce friction when pulling cables through tight conduits.

Do not overapply, as excess lubricant attracts dirt.

Correct Storage for Maximum Longevity

Proper storage is as important as cleaning.

·Rewind carefully into the original case

·Avoid twisting or sharply bending the tape

·Store in a cool, dry environment

These simple precautions significantly reduce structural stress.

Handling Common Wear Issues

Minor splinters can be smoothed using fine sandpaper. Damaged connectors should be replaced promptly to maintain safe operation. Regular checks ensure the tool remains dependable for demanding installations.

Recommended Maintenance Routine

For frequent users:

·Clean lightly after every job

·Perform deeper cleaning weekly

·Conduct detailed inspection monthly

Consistency is key to extending the tool’s lifespan.

Conclusion

Fiberglass Fish Tape is a durable and practical solution for professional cable pulling. With systematic cleaning, careful drying, periodic inspection, and correct storage, its operational life can be greatly extended.

Taking proactive maintenance steps not only improves efficiency but also enhances safety and reduces long-term costs. Properly cared-for Fiberglass Fish Tape will continue delivering stable performance across a wide range of electrical installation projects.

References

GB/T 7714:Bank L C. Composites for construction: Structural design with FRP materials[M]. John Wiley & Sons, 2006.

MLA:Bank, Lawrence C. Composites for construction: Structural design with FRP materials. John Wiley & Sons, 2006.

APA:Bank, L. C. (2006). Composites for construction: Structural design with FRP materials. John Wiley & Sons.