Why Fiberglass Fish Rods Are Ideal for Industrial Wiring

Author:jiujiu Release time:2025-11-20 10:31:56 Number of views:138order

When working on large-scale cable routing projects, technicians rely heavily on tools that can withstand demanding conditions. Among these essential tools, Fiberglass Fish Rods have become a preferred choice across industrial wiring tasks. Their balanced mix of durability, non-conductive safety, and controlled flexibility make them ideal for guiding wires through conduits, ceiling grids, and wall structures.

Whether a project involves upgrading an industrial plant or a manufacturer preparing tools for heavy production use, knowing why Fiberglass Fish Rods outperform other routing options can significantly improve efficiency and safety on the job.

1. Excellent Strength for Pushing Through Long Conduits

Industrial wiring often requires feeding rods through extended conduit paths. Fiberglass Fish Rods are engineered to offer impressive rigidity while remaining lightweight enough for all-day use.

Key Strength Advantages

·Effective directional control in long cable runs

·Strong pushing ability without excessive operator strain

·Maintains structural integrity even after repeated flexing

Because industrial conduits can stretch across multiple rooms or levels, having rods that remain stable under pressure is essential.

2. Balanced Flexibility for Navigating Complex Pathways

Industrial environments typically involve irregular conduit shapes, tight bends, and unexpected obstacles. Fiberglass Fish Rods provide a level of flexibility that supports smooth navigation without compromising push force.

Why Flexibility Is Essential

·Adapts to curves without kinking

·Moves around mechanical equipment and framework

·Avoids excessive tension on cable jackets

This controlled flexibility prevents friction-related damage and keeps cable pulling operations predictable and manageable.

3. Non-Conductive Construction Improves Installer Safety

Electrical safety is a critical concern in industrial environments, where active circuits and high-voltage systems are often present. One of the biggest advantages of Fiberglass Fish Rods is their inherently non-conductive material.

Safety Benefits

·Reduced shock risk compared to metal rods

·Suitable for routing near live electrical components

·A safer choice for confined electrical rooms or panels

This makes fiberglass a dependable option for technicians who must work around energized systems.

4. Designed for Tough Industrial Conditions

Industrial facilities expose tools to demanding conditions—including dust, moisture, chemicals, and temperature fluctuations. Fiberglass Fish Rods are designed to resist degradation from these types of environments.

Durability Features

·Corrosion-resistant construction

·Low risk of cracking or splitting

·Resistant to warping when stored properly

This resilience not only extends the lifespan of the rods but also ensures consistent performance over many wiring projects.

5. Smooth Gliding Performance Reduces Installation Stress

Cable installation efficiency is heavily influenced by friction. The smoother the rod surface, the easier it is to guide through conduits—especially over long distances.

Reduced-Friction Benefits

·Allows easier movement inside conduit walls

·Lessens cable abrasion

·Enhances control when pulling heavy or bundled wire groups

The smooth resin finish on many fiberglass rods helps reduce drag, which is particularly valuable during industrial wiring where cable bundles can be substantial.

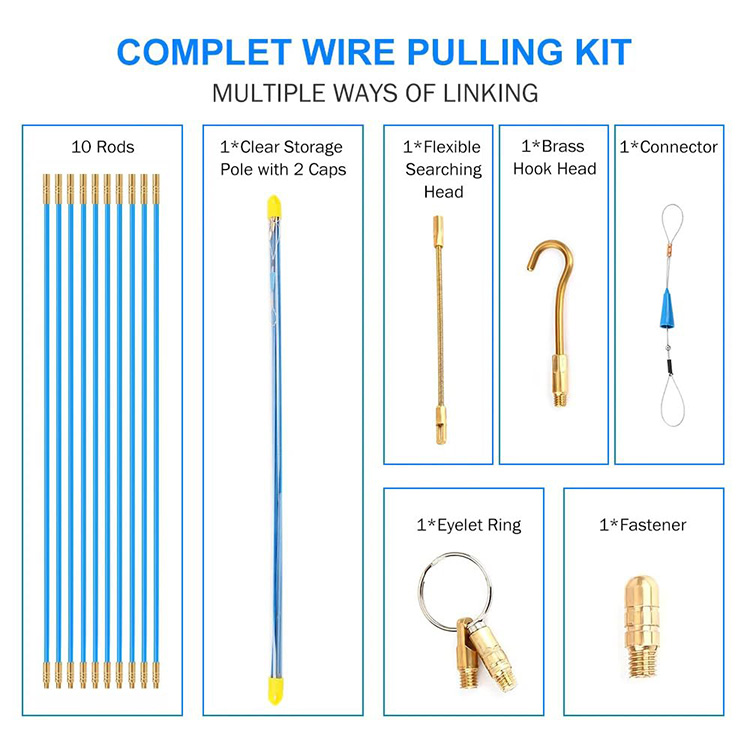

6. Modular Design Provides Versatile Length Options

Most Fiberglass Fish Rods are sold as sectional pieces that can be connected to form different lengths, making them suitable for a variety of industrial wiring situations.

Advantages of Modular Rods

·Configure short or long reaches as needed

·Add specialty heads for targeted tasks

·Reduce the number of tools an installer must carry

Industrial wiring rarely follows a simple path—having adaptable rods gives technicians more control over the routing process.

7. Compatible With Multiple Rod Attachments

Fiberglass Fish Rods work with a wide range of accessories designed to simplify cable routing, especially in hard-to-reach spaces.

Popular Attachments

·Magnetic retrieval heads for lost tools

·Loop ends for gripping cable bundles

·Hook attachments for pulling existing wires

·Illuminated tips for dark or hidden workspaces

These attachments allow installers to work faster and with greater precision.

8. Economical for Bulk Use in Industrial Settings

Organizations that conduct frequent wiring tasks benefit from tools that offer long-term value. Fiberglass Fish Rods provide excellent durability for teams working on multi-site projects or facilities that maintain tools for batch supply.

Economic Advantages

·Fewer replacements needed

·Versatile for multiple installation types

·Reliable for daily or high-volume use

For teams that must equip multiple technicians or maintain tool inventory across several locations, fiberglass rods offer both performance and cost efficiency.

Conclusion: Why Fiberglass Fish Rods Lead the Industrial Market

From insulation safety to outstanding maneuverability, Fiberglass Fish Rods provide the ideal combination of performance and reliability for industrial wiring projects. Their strength, controlled flexibility, and resistance to harsh working conditions make them a dependable tool for installers, technicians, and manufacturers preparing equipment for continuous Production workflows.

Whether guiding cables through complex conduit systems or navigating multi-level industrial structures, Fiberglass Fish Rods consistently deliver smooth performance, improved safety, and long-lasting durability—making them an essential part of any professional wiring toolkit.

References

GB/T 7714:Bank L C. Composites for construction: structural design with FRP materials[M]. John Wiley & Sons, 2006.

MLA:Bank, Lawrence C. Composites for construction: structural design with FRP materials. John Wiley & Sons, 2006.

APA:Bank, L. C. (2006). Composites for construction: structural design with FRP materials. John Wiley & Sons.